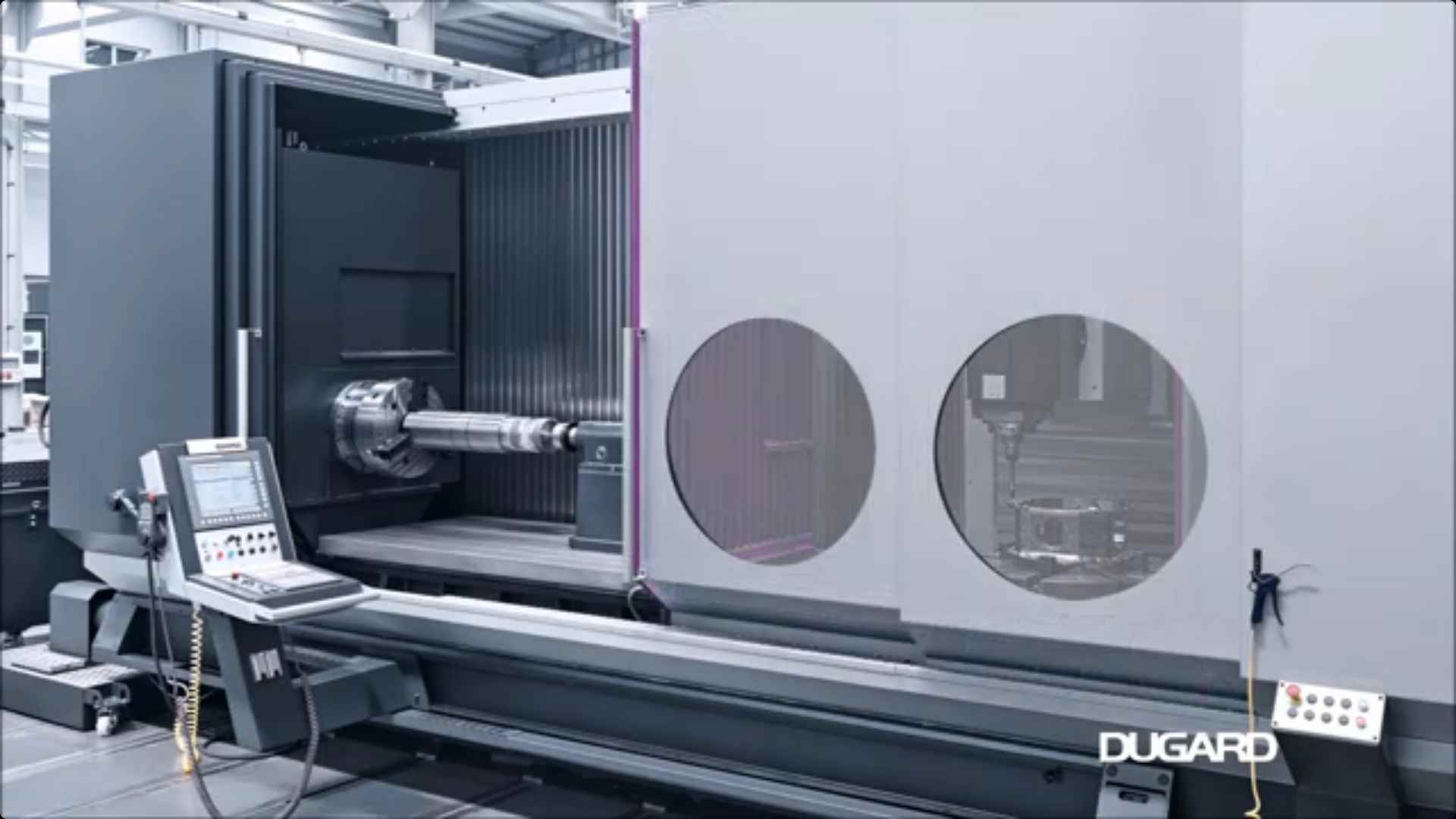

Ibarmia Z Series Multiprocess

Travelling Column Machining/Turning

SPECIFICATIONS

| ZVH40 / 45 / 48 | ZVH50/ 55 / 58 / 60 | |

| X axis travel | 1600~12,000m | 1600~12,000mm |

| Y axis travel | 600~1000mm | 600~1100mm |

| Z axis travel | 900mm | 1100~1300mm |

| Electro Milling Spindle | ||

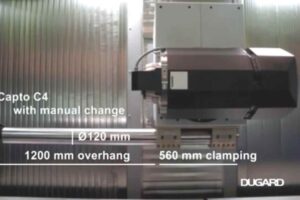

| Standard spindle | HSK63A/Capto C6 | HSK100A/Capto C8 |

| Maximum speed | 12,000rpm | 12,000rpm |

| Power at 100% (S6 40%) | 27/39kW | 74/84kW |

| Torque at 100% (S6 40%) | 130/187Nm | 300/452Nm |

| Optional spindle | HSK63A/Capto C6 | HSK100A/Capto C8 |

| Maximum speed | 20,000rpm | 7000rpm |

| Power at 100% (S6 40%) | 25/40kW | 52/73kW |

| Torque at 100% (S6 40%) | 87/135Nm | 500/700mm |

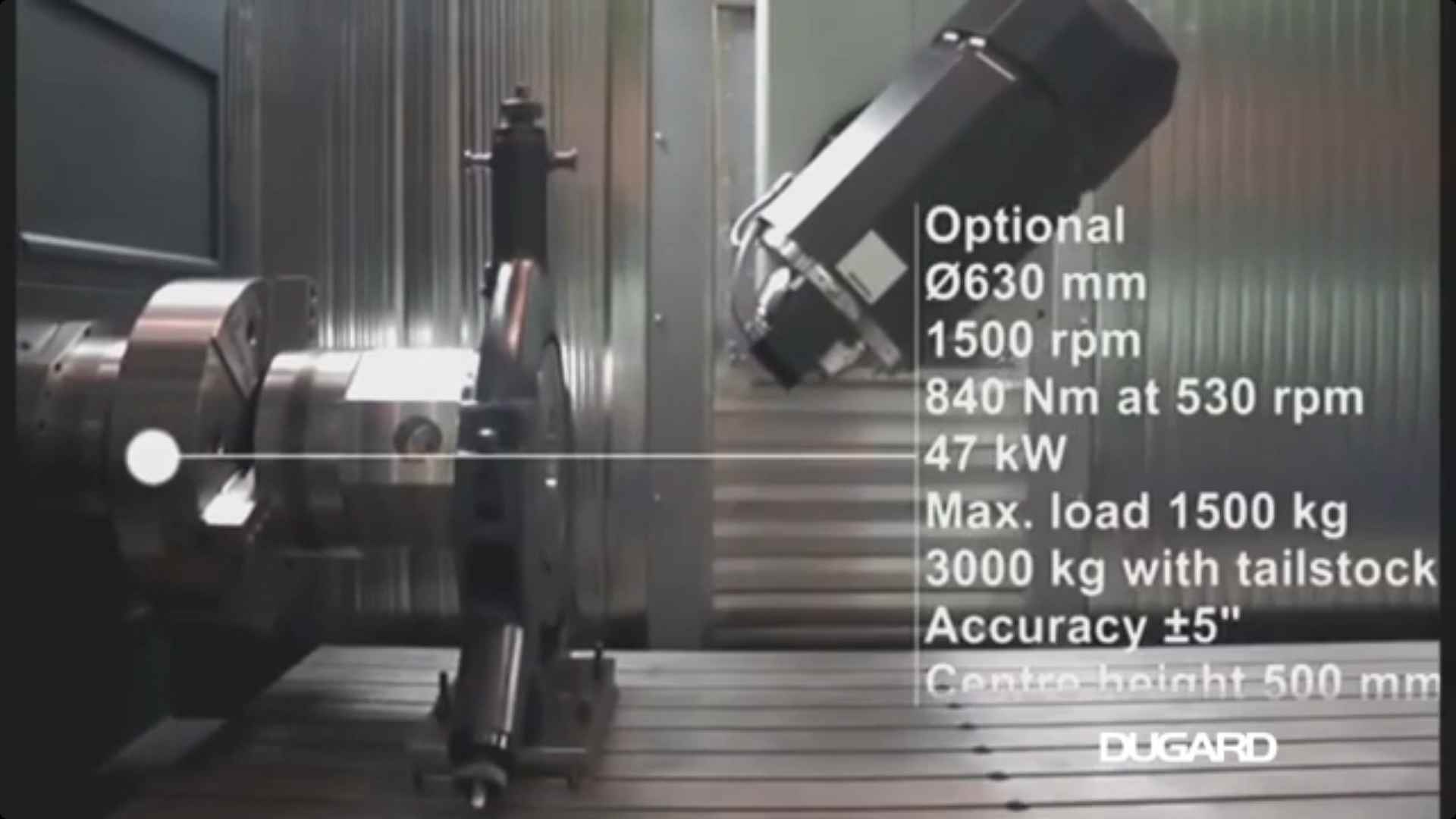

| Built in horizontal rotary table size/swing | Ø800/1100mm | Ø1200/1500mm |

| Table indexing | 0.001° | 0.001° |

| Built in horizontal rotary table with turning function | 800rpm | 800rpm |

| Max horizontal rotary table load | 3000kg | 6000kg |

| Maximum horizontal rotary table load with turning function | 2000kg | 3000kg |

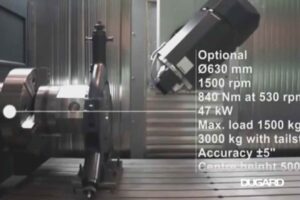

Machine Information

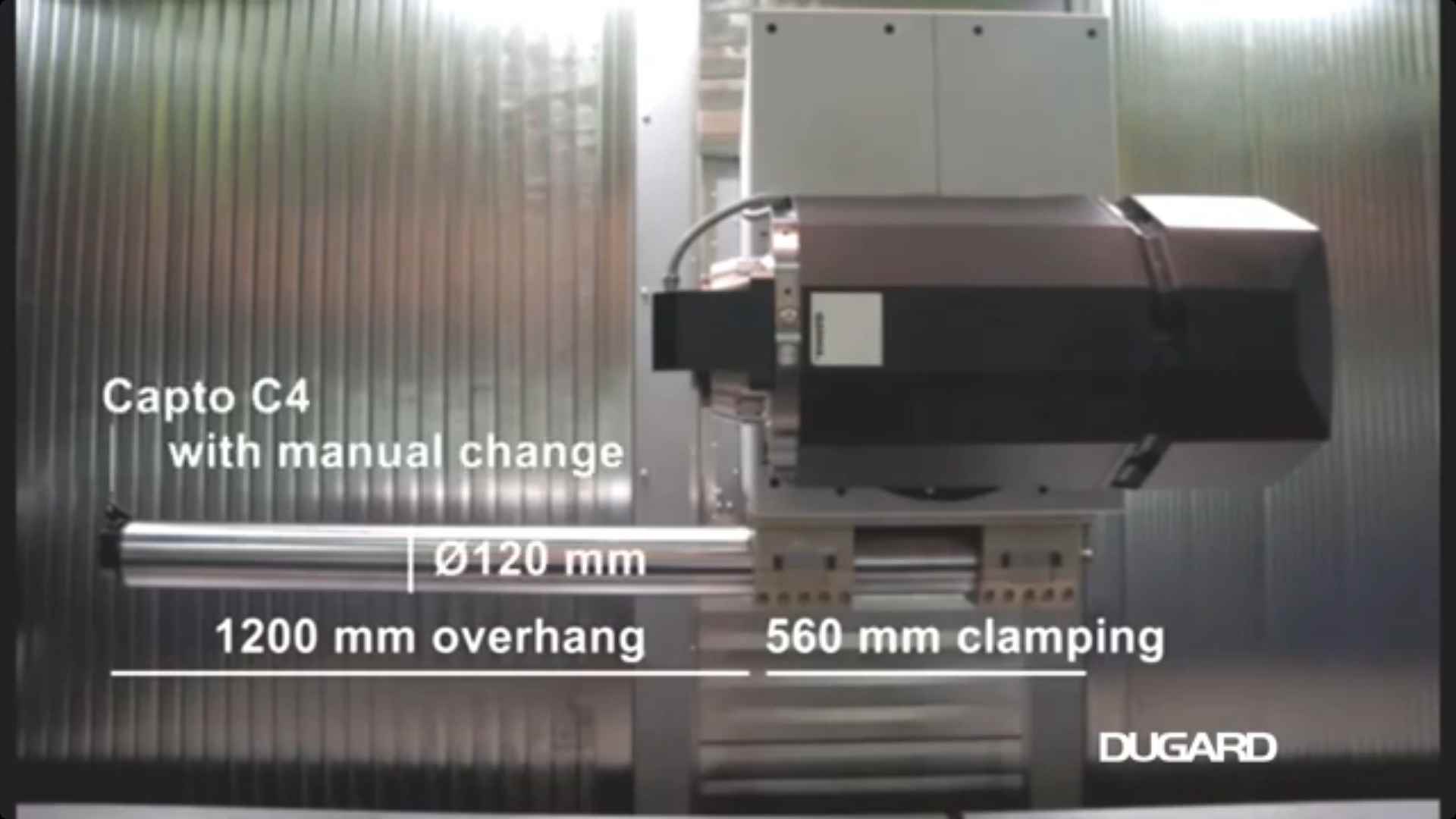

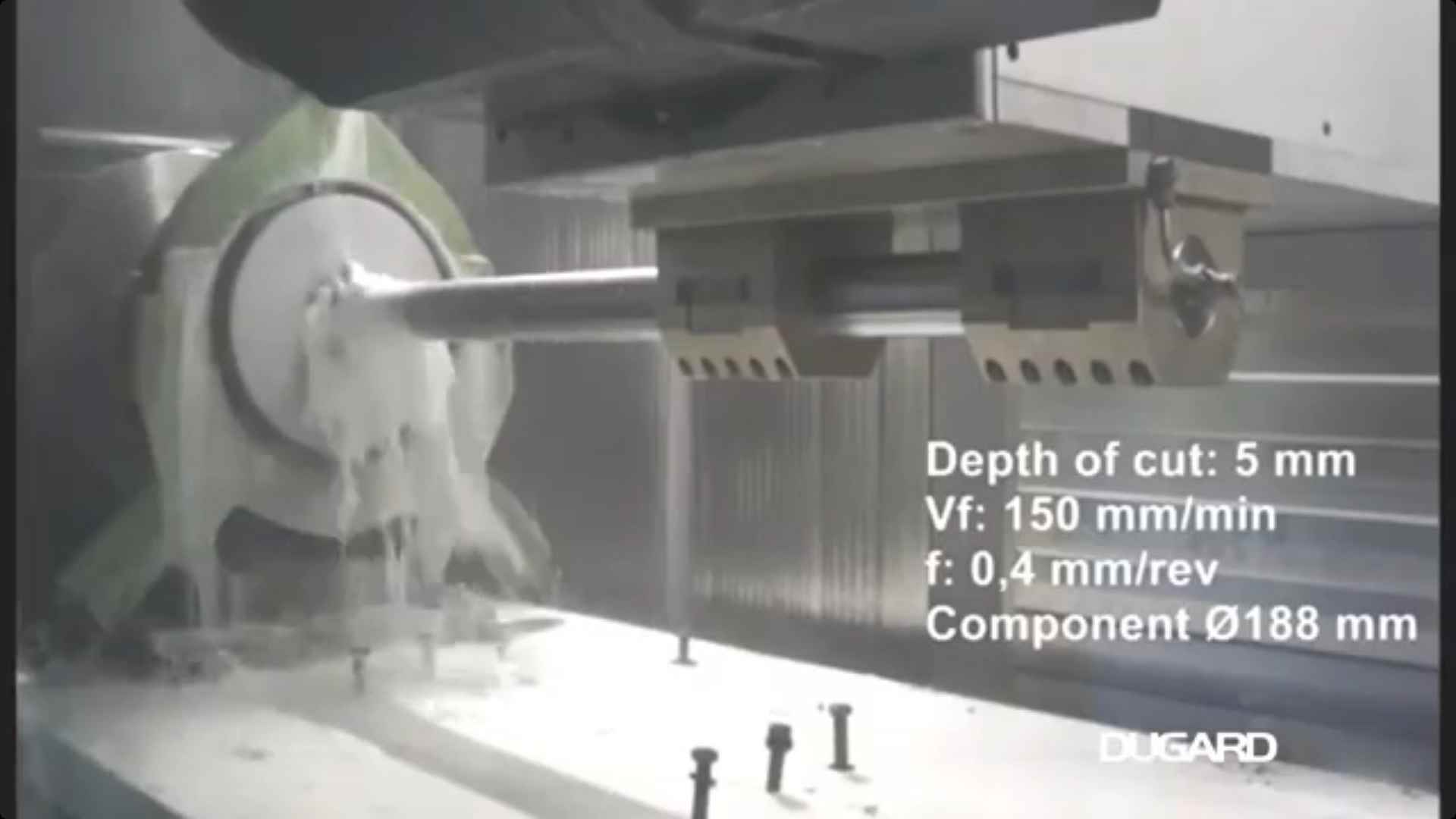

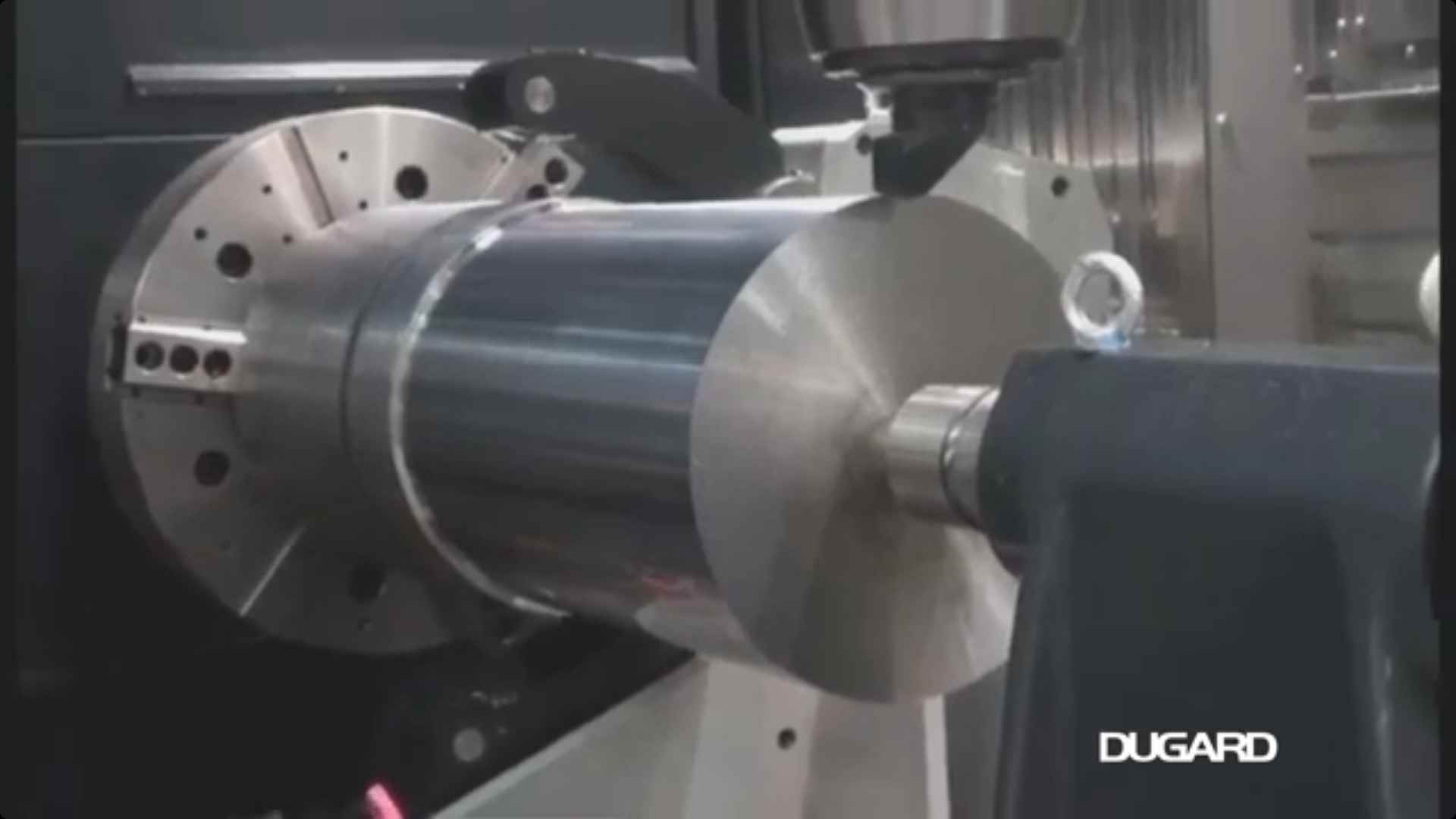

Heavy duty travelling column machining centres capable of serious turning operations, with horizontal and vertical turning from 1.5 to 12m length

Machine Features

Heavy Duty travelling column machining

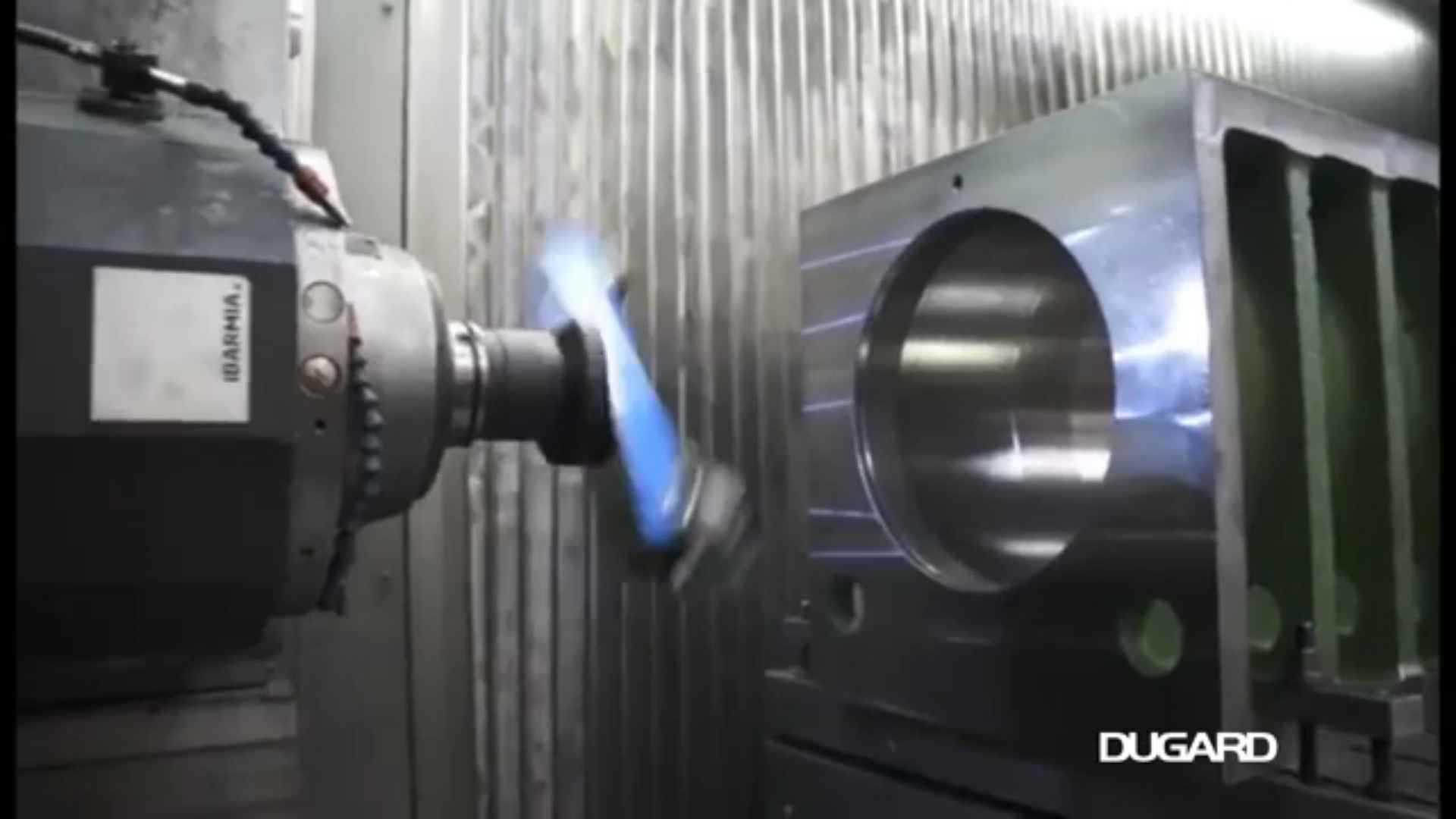

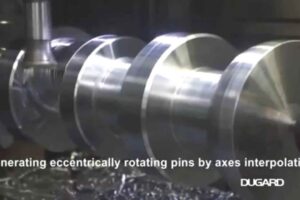

Horizontal and vertical turning

Fanuc, Heidenhain or Siemens controls

| 1500 ~ 12,000mm table travel |

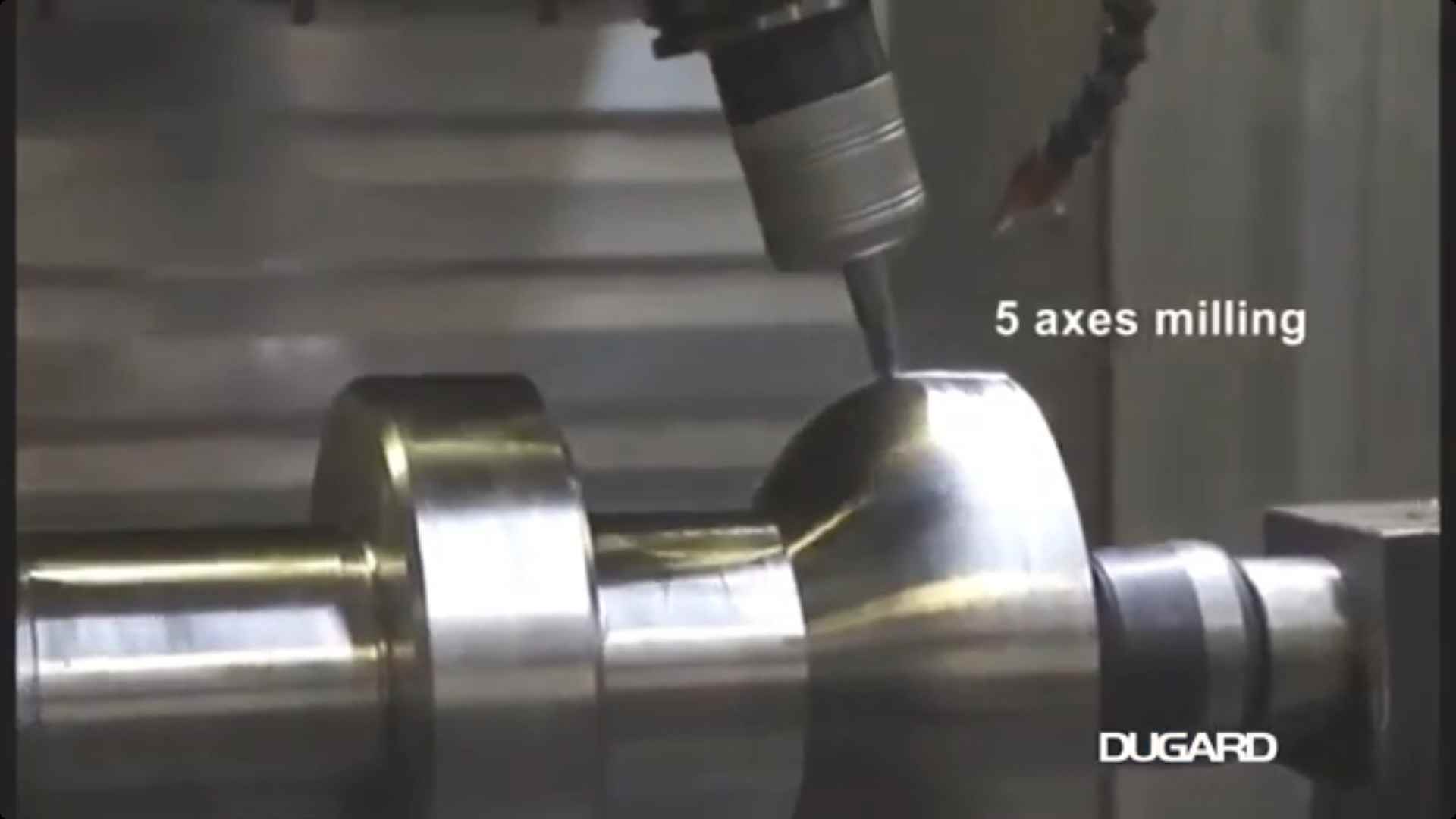

| Rotary table options for 5 axis machining with 1,100mm |

| 24″ power chuck for horizontal turning |

| 6000kg maximum weight between centres |

| Vertical turning function up to 1500mm swing, 500rpm |

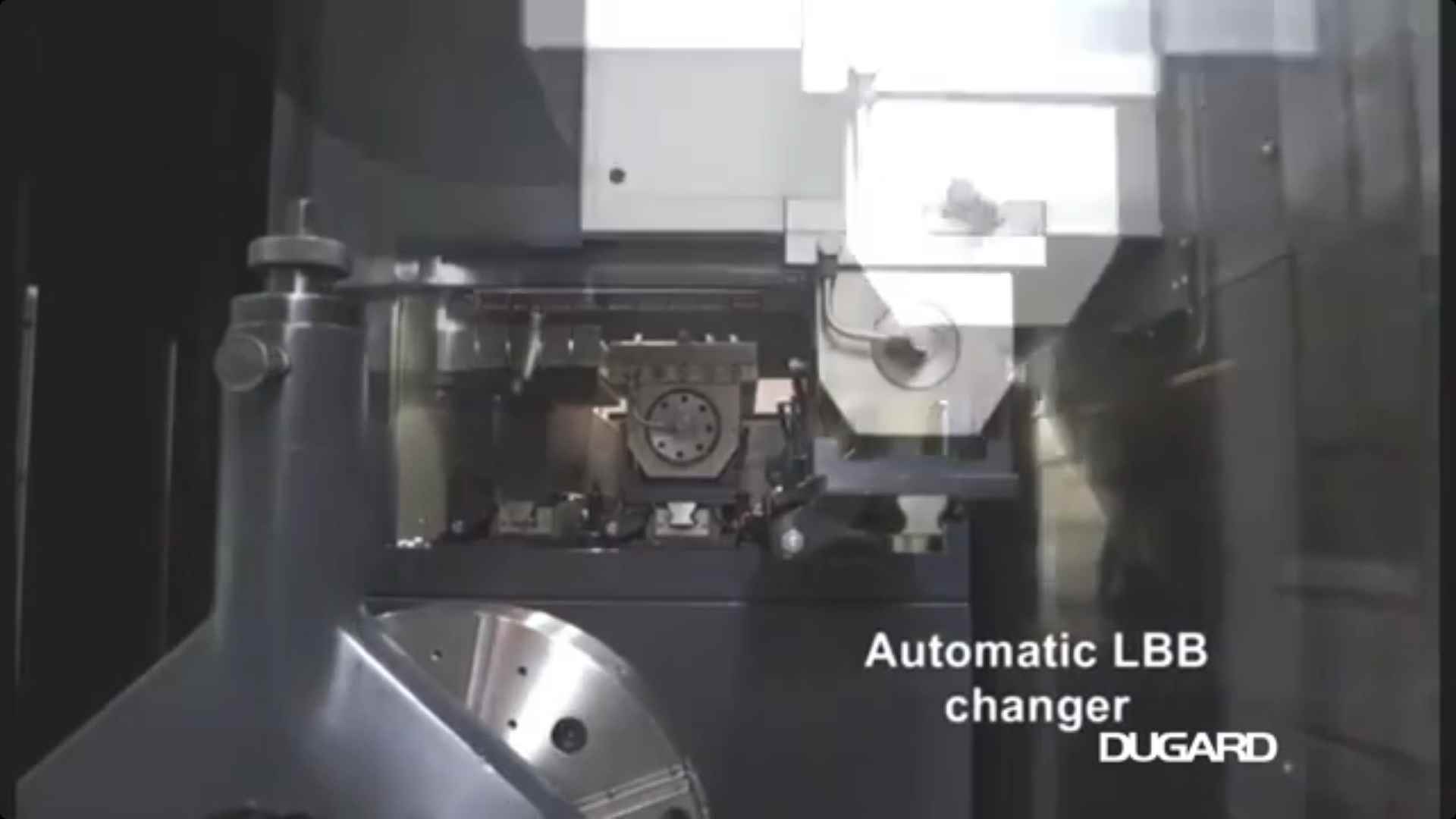

| Table divider for pendulum loading |

| Linear scale feedback on all axes |

| BT40/HSK63/Capto C6/BT50/HSK100/Capto spindle options |

| Up to 74kW spindle power |

| Up to 24,000rpm |